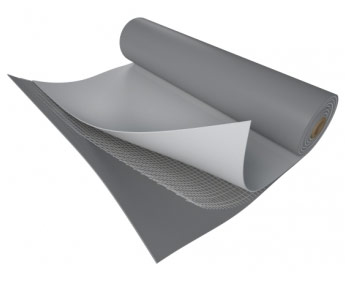

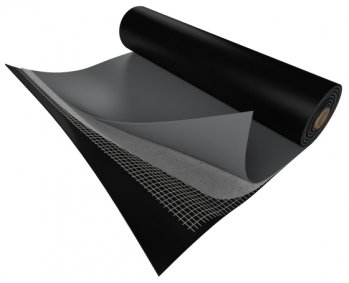

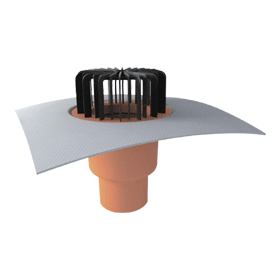

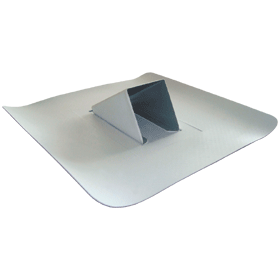

mPVC membrane

mPVC damp proof membranes

Membrane systems can be applied in poor weather conditions (when there is increased dampness in the substrate and atmosphere, and at temperatures down to -5 °C), so they can be installed without any problems throughout the year!

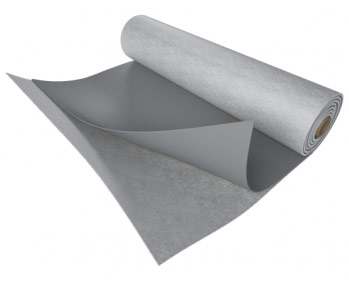

Damp proof membranes are highly resistant to atmospheric exposure, structurally strong and resistant to mechanical stress. They have very good chemical resistance when exposed to extreme atmospheric conditions, and are highly permeable to water vapours and resistant to overgrowing plant roots. They have excellent weldability and impose a minimal additional load on the roof’s load-bearing structure. They have a minimal fire load on the building, and pose a zero risk in terms of health and environmental protection.

Nowadays, it goes without saying that customers can take their pick of various colour shades of damp proof membranes for flat roofs, terraces, and swimming pools, including anti-slip variants, e.g. for swimming pool steps and walking surfaces.

Methods of application:

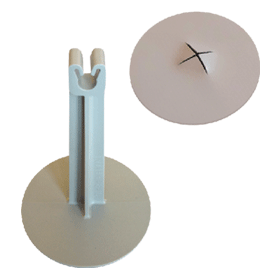

- mechanically anchored systems

- systems with additional load added (pavement, pebbles, green roofs)

- glued systems

- vacuum-protected systems (systems based on the wind suction principle)

- a combination of the above methods

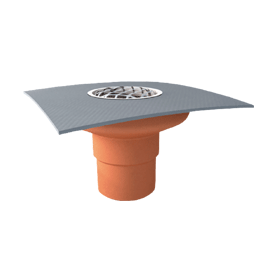

The advantages of flat roof damp-proofing using a PVC membrane include the fact that, unlike other types of damp-proofing materials, the membrane is flexible, so it can withstand dilatation changes in the substrate.

Thermal insulation material can also be laid under the damp proof membrane, which further improves the properties of the roof.

When reconstructing your existing roof, the damp proofing membrane can be laid on to the original surface, so there is no need to remove the old insulation material.

Requests for information and calculations are provided free of charge

You can contact us in writing, over the phone, or by email.